Döllken ABS edgebands

The special features of Döllken ABS edgebands

Döllken ABS edgebands are manufactured using the extrusion process and are fully imbued. Uniform imbuing of the material permits clean and straightforward edgeband rounding. The impact-resistant material constitution of the Döllken ABS guarantees smooth processing on the fabricator system, and many years’ usage as furniture. A special formulation has been developed by SURTECO GmbH for ABS edgebands which guarantees long service lives for milling and other cutting tools. Döllken ABS edgebands are coated on the back with a universal bonding agent which permits perfect bonding of the edge on the carrier material in conjunction with all suitable hot-melt adhesives, and all solvent-based adhesives.

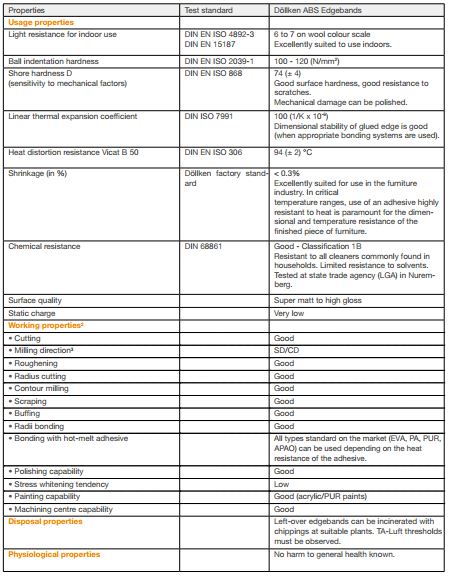

When not bonded, Döllken ABS edgebands have very low “free shrinkage” values. The deformation resistance of ABS edgebands is also positive here – material softening does not occur until 94 (± 2) °C (Vicat B 50).

ABS material characteristics

ABS (acrylnitrile, butadiene, styrol) is an impact-resistant, mechanically and thermally resistant, premium quality thermoplastic synthetic with a positive eco-balance. This chlorine-free synthetic has been deployed successfully in the furniture industry for more than 25 years. It has been the excellent application, working and disposal properties of ABS in particular which have contributed to its broad market penetration in furniture production.

Application areas of Döllken ABS edgebands

The spectrum of applications for Döllken ABS edgebands is virtually unlimited – from the office, bathroom and kitchen, shop and exhibition stand construction, and accommodation areas right up to all types of fixtures and fittings. The particularly application-friendly raw material formulation of the Döllken ABS enables straight working as well as smooth deployment on all curved furniture geometries, irrespective of whether inner or outer radii are required. Given the impressive disposal properties, ABS edgebands are becoming an absolute stipulation in many public and private tenders.

Processing information

Machine Processing

Döllken ABS edgebands can be used on all edge glueing machines with hot-melt technology. Bonding, cutting, milling, working with the draw blade and subsequent processing with polishing wheels and hot-air apparatus for high quality surfaces are possible without problem. A few central process parameters need to be observed for clean and permanent edge coating, which are currently dependent on the materials used (edgebands, adhesives, boards), the edge glueing machine and the ambient temperatures. Determining the best settings with trial and error is therefore recommended in each case. The guideline values specified by the manufacturers for the respective applications must be observed.

Adhesives

All hot-melt adhesives available on the market (EVA, PA, APAO, PUR) can be used with Döllken ABS edgebands. Adhesives highly resistant to heat, together with the low-shrinkage raw material formulation of the Döllken ABS, guarantee reliable bonding even for edgebands thicker than 3 mm. Adhesives which are particularly resistant to heat are recommended for high application temperatures, such as in the cooking area in the kitchen, and in containers for furniture export. In the bonding process, it is important to always ensure there is a sufficient amount of adhesive in the container – to guarantee a constant temperature when the adhesive is applied. The working temperature of the adhesive varies between 90 and 220°C depending on adhesive type. Please note that the thermostats in the melt container are often inaccurate, and can vary considerably from the actual temperature at the applicator roller. Measuring the temperature at the applicator roller is therefore recommended. Using the edge glueing process to bond Döllken ABS edgebands with PVAC glue is not possible.

Adhesive amounts to be applied

Please follow the specifications from adhesive manufacturers. The application of adhesive should be uniform and liberal enough such that no small beads are pressed out at the edges of the freshly bonded edgeband, and that the cavity between wood splints is filled. The amount of glue applied is dependent on the chipboard density and adhesive type.

Working temperature

To achieve best possible results in edgeband coating, boards and edgebands should be at room temperature (not below 18°C). When material is stored outside, it should be warmed up overnight. When boards or edgebands are too cold, the hot-melt adhesive applied sets before the edge strip is applied. Draughts should therefore be avoided for this reason.

Wood moisture

The optimum wood moisture of the board material for processing is between 7 and 10%.

Feed rate

The special raw material formulation of Döllken ABS edgebands is aligned to the feed rate at the small-scale fabricator as well as to that standard in large-scale industry. Rates from 10 to 100 m/min are possible depending on the edge glueing machine. Rates of 30 m/min are possible on modern portal machine centres depending on geometry.

Pressure rollers

To attain the best possible seam appearance, ensure that the correct number is present and that the pressure setting is correct – taking into consideration the machine conditions.

Milling

Ideally use 3 to 6-blade milling cutters with speeds of 12,000 to 18,000 rpm. Incorrect speeds and blunt tools can damage the edgebands. If lubrication effects occur, the speed of the miller must be reduced, or milling must be in the counter direction (increase feed rate as required).

Scraping

Because the ABS material tends to lighten slightly after scraping, the maximum draw blade size should be 0.1 – 0.2 mm. The milling required here, as free of chatter marks as possible, is guaranteed by milling tools with high levels of concentricity. The use of DIA tools is helpful. Hot-air units which simply coat any stress whitening occurring as required can be used for further optimisation of scraping, especially for critical colours.

Buffing

Döllken ABS edgebands can be worked very well with the polishing wheel within the radius. Any light spots arising from scraping can simply be polished away with polishing wheels, and the colour of the radius corresponds to the edge strip surface. Glue residue can also be removed using a polishing wheel on edge strip glueing machines working in passthrough mode. Also, glue residue can be removed with electronically controlled separating spray units used as standard in the industry. This also improves draw blade chip removal at the same time.

Extraction

Thermoplastic edgebands require stronger extraction than thermoset edgebands. The lower static charging compared to other thermoplastic raw materials is a benefit of Döllken ABS edgebands.

Manual processing

Döllken ABS edgebands can also be worked manually without problem, such as by using a glueing press or edgeband press. 2-component dispersion adhesives based on acrylic, and suitable contact adhesives, are recommended as adhesives here. Please contact your adhesive supplier for information. Bonding using 1-component wood PVAC glue is not possible. Special lacquer glues, solvent-based adhesives and rubber adhesives (PU) can be used when bonding by hand. We will be glad to provide you a list of types on request. Bonding should take place at room temperature. When contact adhesives are used, it is important to observe the ventilating time after adhesive is applied to the board and edgeband so as to guarantee optimal edgeband bonding. Then the edgeband is tapped. When dispersion adhesives are used, there must be no acceleration of the bonding process using temperature (with heating rails for example). Subsequent processing can start after hardening has taken place (up to 6 hours depending on adhesive).

Stationary working

Döllken ABS edge strips can be worked excellently on machining centres. Even tight radii are possible, as long as you bear a few things in mind. The following exert a significant influence over the working process:

- Edgeband designs (dimension, base colour, etc.)

- Ambient and material conditions (temperature, moisture of material)

- Adhesive properties (type, temperature, viscosity)

- Machine equipment (edgeband pre-warming, pressure, type of glue applicator roller)

- Work step programming (feed rate, offset, pressure)

For imprinted edge strips, tighter radii than with UNI edgebands can generally be realised because potential stress whitening is, to a certain degree, covered by printing inks. We will be glad to provide more information on request.

Product characteristics

Seam appearance

Because Döllken ABS edgebands are supplied from the factory with defined pre-tension and plane parallelism, they are always given a compact, visually perfect seam appearance. The pre-tension also ensures best possible bonding with inclusion of excessive adhesive in the centre of the back of the edgeband, and embedding of the adhesive in the chipboard.

Mechanical properties

Wear resistance

UV-hardened acrylic lacquer is used to seal the surfaces of imprinted Döllken ABS edgebands so as to be scratch-resistant. The print patterns also exhibit excellent resistance to scratches and wear. They satisfy Stress Group 2E, DIN 68861.

Ball indentation hardness/Shore hardness D

Döllken ABS also attains very good results for surface hardness in line with DIN EN ISO 2039-1 and DIN EN ISO 868.

Thermal properties

Heat distortion resistance

With a value of 94 (± 2) °C to Vicat B 50, Döllken ABS edgebands are excellently suited for use in the furniture industry and for internal fittings. Döllken ABS edgebands are inflammable, just like derived timber products. Pyrolysis does not start until 300°C.

Chemical properties

Döllken ABS edgebands are resistant to all cleaners and substances commonly found in households (such as food acids) in line with DIN 68861. Also, Döllken ABS edgebands have been tested by the state trade agency (LGA) in Nuremberg, and satisfy Stress Group 1B.

Paint

Uni-colour Döllken ABS edgebands can be painted in the colour you require without any problems and without pre-treatment. Use PUR paints or acrylate-based paints. Never use nitro-cellulose paints. More information on the paint type best suited is available from the respective paint supplier

Resistance to fading

Using a special process in the SURTECO GmbH technical centre, ABS edgebands undergo continual testing with respect to resistance to fading. With a light resistance figure of 6 to 7 on the wool colour scale, they are perfectly suitable for indoor use (DIN EN 15187).

Surface quality

Döllken ABS edgebands are available on a gloss level from super matt to high gloss. Furthermore, a number of different surface imprints are available, which can be combined with the gloss level and the colour or decorative finish.

Technical details

2 Machine optimisation may be necessary.

3 Counter direction is recommended for all thermoplastic materials: SD = Same direction, CD = Counter direction

If not explicitly specified otherwise, the values given were determined on standardised test specimens at room temperature. The figures are to be regarded as guideline values, not binding minimum values. Please note that properties can be influenced greatly by tool design, working processes and colouring.